Oracle SCM Functional Interview Questions

& Answers - Order Management Module - Part VI

Question

& Answers on Shipping & Execution

Define

Release Rules:

Release Rules is defined as the

criteria to be used during Pick Release. Only sales orders which meet the

criteria and are eligible will be released. A Sales Order line is eligible if

it has completed the prerequisite workflow activities, such as Schedule -

Line or Create Supply.

Define

Release Sequence Rules:

Release Sequence Rules determines

the order in which inventory is allocated to sales orders. Users can

choose to allocate by order, outstanding Invoice value, Scheduled

Date, Departure Date & Shipment Priority.

The Sequence in which sales orders are

filled could be very important. If a company has a problem of running out of

material before all of their orders have been filled it is very important that

they have filled their most important orders first.

Define

Picking Rules:

Picking Rules which are created and

maintained in Inventory, suggests which material to use, based

on inventory controls such as Revision control, Lot control, FIFO

(first in first out) or subinventory / locator picking numbers.

Picking Rule is an Item Attribute.

Create a variety of picking rules and associate them with the appropriate

items. If there isn’t a Picking Rule associated with the item, the system will

use the Organization’s default Picking Rule which is defined in the Shipping

Organization’s Parameters.

Define

Pick Slip Grouping Rules:

Pick Slip Grouping Rules organize how

released order lines are grouped on Pick Slips for ease of picking.

Example: By using the Pick Slip

Grouping Rule "Sub-Inventory" the user can reduce the number of trips

to a particular sub-inventory by grouping all lines for that

sub-inventory on to one Pick Slip.

What

Happens during Pick Release?

1. A pre-approved Move Order is

automatically created in Inventory.

2. A Move order is a request for a

subinventory transfer from the source subinventory to the destination (staging)

subinventory.

3. A Move order is created for every

Sales Order Line that has the status of “Awaiting Shipping” and passes the

picking criteria.

4. The Destination subinventory is the

Staging subinventory entered on the Release Sales Orders form or defaulted from

the Shipping Parameters. Only one staging subinventory is allowed per Picking

Batch.

Note: A Picking Batch is the total

number of Order Lines that were released at one time.

Inventory uses the move order to

manage material requisitions within an Organization.

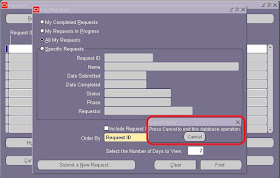

Other

options during Pick Release:

Allocate Inventory to the move order:

Allocating can be done automatically

after the move order is created by setting “Auto Allocate” to yes on the

Release Sales Order form or postponed until later, then manually allocated from

the Transaction Move Orders form.

The Release Sequence Rule,

that was entered on the Release Sales Orders form, or defaulted from the

Shipping Parameters, will be used to determine in what sequence to

fill the move orders.

Pick Confirm the move order:

Pick Confirm can be done automatically

during the picking process by setting “Pick Confirm” to yes on the Release

Sales Orders form or by unchecking the Pick Confirm Required checkbox in the

Organization Parameters form. If it is not done automatically during pick

release it can be done manually from the Transaction Move Orders form by

selecting the Transact button.

The Pick Confirm transaction executes

the subinventory transfer, moving the material from it’s source location to

it’s destination staging location. Only 1 staging subinventory is supported per

picking batch.

Auto Create Deliveries – Optional:

A delivery is required in order to Ship

Confirm. User can select to have the Picking process automatically group the delivery

lines into deliveries to expedite this process.

Reference: Collected

from various web sources

Please do refer: