Oracle

Inventory – Inventory Controls:

Oracle Inventory provides Inventory Controls to control /

track individual items or a group of items when transactions are performed in

an organization.

Example:

If a car manufacturer realized that one of the component

of the Brake assembly is not working properly as there are lot of similar

complaints by many customers. In order to track the Brake assembly manufactured

using that component lot number. Likewise for Pharmaceutical industry to

control the expiry date of the medicine.

Any combination of the below inventory controls can be

implemented for each item.

1. Locator Control

2. Revision Control

3. Lot Control

4. Serial Number Control

Inventory controls are optional for all items, it can be

defined for specific items also.

1. Locator Control:

Locators are structures within sub inventories. Locators

are the third level structuring of Oracle Inventory. Locators may represent row,

bin or rack in the organizations. So that the items can be received and ship

directly into & from the defined locators.

During a material transaction, Oracle Inventory checks

the specified locator control options. If the Locator control is enabled, then

a valid locator should be entered where the parts are to be receive or from

which locator the part is to be issued for the transaction.

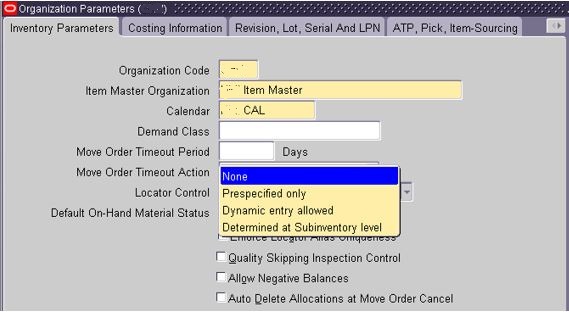

Navigation:

India Local Inventory > Oracle Inventory > Setup

> Organizations > Parameters > Inventory Parameters Tab

Locator Control

Options:

None:

Inventory transactions within this organization do not require locator

information.

Prespecified only:

Inventory transactions within this organization require a valid,

predefined locator for each item.

Dynamic entry allowed:

Inventory transactions within this organization require a locator for

each item. A valid, predefined locator, or define a locator dynamically can be

chosen at the time of transaction.

Determined at sub inventory

level:

Inventory transactions use locator control information that is defined

at the sub inventory level.

Hierarchy:

Oracle Inventory uses the below hierarchy to determine

which locator control option to enforce during the transactions:

1. Org level overrides sub inventory and item level

2. Sub inventory level overrides item level

3. If decision is to item level, Oracle Inventory uses

item level.

2. Lot Control:

Oracle inventory provides a complete lot number support

for the inventory transactions. Lot can be enabled for a specific item in an

inventory org. For the items under lot control, Lot number to be assigned

during each receipts into the inventory org and thereafter the same lot number

to be referred for every material transactions and even while taking

Miscellaneous receipt for the items.

Lot control is a technique for enforcing the use of lot

numbers during material transactions, thus enabling the tracking of batches of

items throughout their movement in and out of inventory.

Lot number is to identify a specific batch of an item

that is received and stored in an organization. An inventory receipt can be

split into several lots, based on business requirement. Quantities can be added

to existing lot numbers. Inventory will generate default lot numbers by using

the default lot number generation method which is configured in the

Organization Parameters window.

Navigation:

India Local Inventory > Oracle Inventory > Setup

> Organizations > Parameters > Revisions, Lot, Serial And LPN Tab

Lot Number

Uniqueness:

Across items:

Enforce unique lot numbers for items across all

organizations.

None:

Unique lot numbers are not required.

Lot Number Generation

Option:

User-defined:

You can define a lot number for an item when you

receive it.

At organization level:

The system uses values you enter in the Prefix, Zero Pad

Suffix, and Total Length fields to automatically generate a lot number for an

item when you receive it.

At item level:

The system uses the starting lot number prefix and the

starting lot number that is defined in the item master to automatically

generate a lot number for an item when it is received.

Indicate whether to add zeroes to right-justify the

numeric portion of lot numbers (Zero Pad Suffix).

Optionally, select an alphanumeric lot number prefix to

use for system-generated lot numbers when lot numbers are generated at the

organization level.

Optionally, define the maximum length for lot numbers.

3. Serial Number Control:

Oracle inventory provides complete serial number support

for the inventory transactions. Serial number control can be enabled for

specific items in an inventory org.

For items under serial number control, you assign unique

serial numbers to individual units and thereafter reference the same serial

numbers each time you perform material transactions.

Serial number is an alphanumeric piece of information

assigned to an individual unit of an item. A serialized unit is a

combination of an item number and a serial number.

Individual units of items can be tracked by using serial

numbers. Serial number control is a system technique for enforcing the use of

serial numbers during a material transaction. Serial numbers can be used to

track items over which a very tight control is to be maintained.

Navigation:

India Local Inventory > Oracle Inventory > Setup

> Organizations > Parameters > Revisions, Lot, Serial And LPN Tab

Serial number

uniqueness:

Within organization:

Enforce unique serial numbers within the current

organization.

Within inventory items:

Enforce unique serial numbers for inventory items.

Across organizations:

Enforce unique serial numbers throughout all

organizations.

Serial Number Generation

Option:

At organization level:

Define the starting prefix and serial number information

for items using the information you enter in the following fields of this

window.

At item level:

Define the starting serial number prefix and the starting

serial number when you define the item.

Optionally, select an alphanumeric serial number prefix

to use for system-generated serial numbers when generation is at the

organization level.

Optionally, enter a starting serial number to use for

system-generated serial numbers.

4. Revision Quantity Control:

Revision quantity control can be defined for any item to

track quantities by revision. If Revision quantity control is enabled for an

item, then a revision number to be provided during the every transaction of

that item.

Defining an Item under Revision Control:

Item can

be placed under revision control by checking the box `Revision control` in

Inventory tab while defining new item or for existing item.

Transaction cannot be performed without specifying a

valid Revision for the item under revision control. Revision control cannot be

changed when an item has on-hand quantity.

Different revisions can be defined in different

organizations if not defined at master level.

Nice blog..! I really loved reading through this article. Thanks for sharing.You done a great job.Oracle SCM Training Institutes in Bangalore

ReplyDeleteGood knowledge post for this information

ReplyDeleteOracle Apps Technical training in bangalore